Pincourt Interior Painting for brighter mornings and flawless walls

Open, light-filled rooms with interior painting in Pincourt

Why most interior painters in Pincourt fall short

| What clients often get elsewhere | What Walls Painting does differently |

|---|---|

| Rooms feel cramped by outdated dark colors. | Light-smart palettes open and brighten rooms. |

| Roller lines and brush marks show. | Glass-smooth walls, no strokes or lines. |

| Shrunken caulk leaves gaps at trim. | Seamless, tight caulk and crisp trim. |

| Yellowed ceilings make spaces look tired. | Bright, clean ceilings that lift light. |

Talk to the interior painters Pincourt trusts.

About us

We know how heavy or dated colours can make rooms feel small, how uneven roller marks, gaps in caulking, yellowed ceilings, and peeling paint steal pride from your home. At Walls Painting, we listen and treat your space with care.

We refresh every surface with smooth, durable finishes and timeless colours that reflect natural light, create seamless flow, and feel modern for years. Our interior painting Pincourt team works around your schedule, delivering rooms that look bigger, calmer, and new.

Homeowners choose Walls Painting for friendly pros, tidy sites, and results that last. We’re local, responsive, and consistently rated 5/5 on Google—proof you can trust the care, detail, and respect we bring into your home.

What our loyal customers say about us

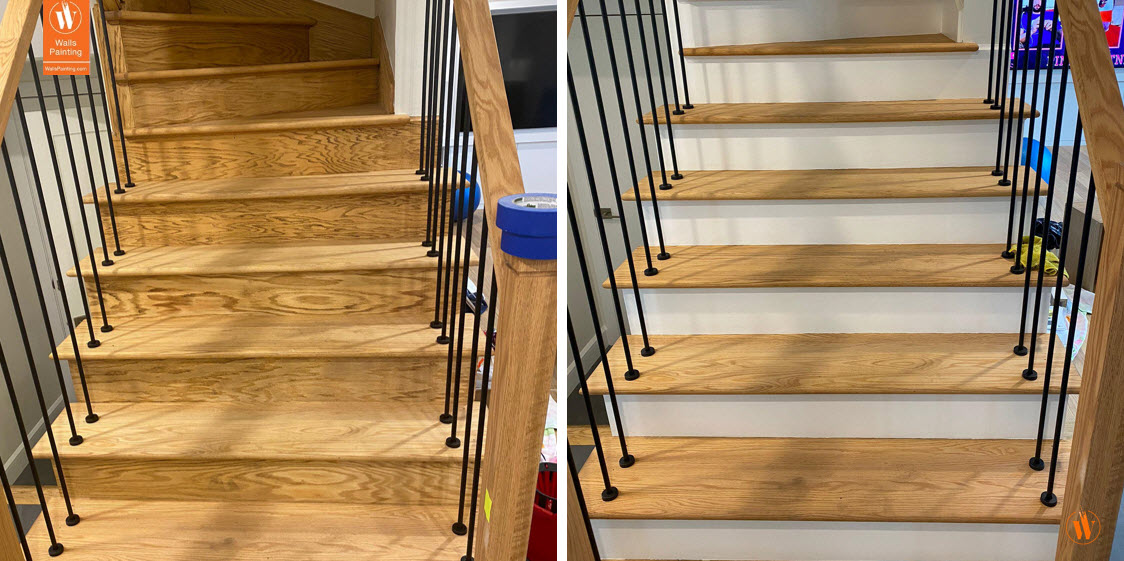

Our Signature in Action

Discover a selection of our most impactful projects, showcasing the quality, creativity, and expertise we bring to every client collaboration

Simple, Proven Interior Painting in Pincourt

Plan & Clear Quote

As your interior painters in Pincourt, we confirm colors, finishes, and timing—then deliver a clear, firm quote.

Prep, Protect, Paint

This is interior painting Pincourt homeowners trust—repairs, caulking, priming, and low-odor paint for smooth, bright rooms that feel bigger.

Final Walkthrough & Warranty

With Walls Painting, we inspect every detail, tidy up, and back our work—so you enjoy flawless rooms, worry-free.

Choose the right interior service

Choose a palette that opens your space, reflects natural light, and still feels timeless years from now. We guide undertones and sheen so rooms flow seamlessly and mornings feel brighter.

From sanding ridges and fixing roller marks to repairing failed adhesion, gaps, and yellowed ceilings, we create walls so smooth they look new—clean lines, invisible patches, and flawless finishes that won’t highlight imperfections.

Refresh baseboards, windows, and doors with sharp lines, renewed caulk, and durable enamels. Tight gaps disappear, edges look like custom carpentry, and every transition feels tidy, elevating your whole home at a glance.

Not sure where to start? Speak with a Walls Painting representative—we’ll map the best approach, timeline, and budget for your home.

Our Commitment: Guidance, Care, Follow-Through

Every project is structured with a clear scope, transparent pricing, and a shared timeline. Walls Painting uses proven prep standards, detailed checklists, and tidy job sites—from ceiling repairs to trim—a thoughtful, accountable process.

You’ll have a dedicated point of contact, regular updates, and on-site walkthroughs before, during, and after. Questions get answered quickly, decisions are guided, and next steps are always clear—no surprises, just steady communication.

From flexible scheduling to finish recommendations, we adjust to your home’s rhythms. We advise on moisture-resistant baths, sheen levels, and color testing—delivering interior painting Pincourt homeowners can navigate comfortably, with courteous crews and daily wrap-ups.

At Walls Painting, ethics, clarity, and respect guide every step—because doing the right work matters.

Interior painting, available across our neighboring communities

Join many happy clients across Monteregie who have experienced the transformation of their homes. With Walls Painting, satisfaction is not just promised, it’s guaranteed !

FAQ

How does Walls Painting handle interior painting Pincourt projects to brighten rooms and make spaces feel larger while working within the limited contractor windows common in the area?

🖌 Color strategy to brighten and visually expand rooms

We begin by assessing daylight, fixture temperature, and reflectance to specify high-LRV palettes that push light deeper into the space. For cohesion, we favor a continuous main hue across adjacent areas, ceilings tinted 10% lighter, and trim in satin or semi-gloss to reflect light without harsh glare. Cooler undertones balance Pincourt’s warm afternoon light, while soft off-whites, pale greiges, and muted pastels reduce visual contrast and make boundaries recede. These choices are tailored to interior painting Pincourt conditions so rooms feel brighter and appear more open.

🖌 Efficient prep and fast-curing systems for limited contractor windows

Preparation is sequenced by zone to fit short access blocks: dust-controlled sanding, precise repairs, and pre-masking allow rapid, clean transitions between coats. We use bonding primers and advanced acrylics with 30–120 minute recoat times, supported by measured airflow and dehumidification to keep curing on schedule. Tools are matched to the substrate—fine-finish rollers or HVLP for doors and trim—to achieve coverage targets in fewer passes. Low-odor, low- or zero-VOC products are prioritized to suit interior painting Pincourt jobs where occupancy and ventilation windows are tight.

🖌 Scheduling, coordination, and quality control in Pincourt

Before work, we confirm building rules, elevator bookings, and municipal quiet hours, then build a room-by-room plan with daily milestones and defined arrival/departure windows. Tasks are phased so one area dries while another is painted, minimizing downtime inside limited contractor windows common locally. Communication is structured: morning start notes, mid-day status, and end-of-day punch updates, with brief onsite walkthroughs when feasible. Quality controls include raking-light inspections, edge-line checks, and color verification, aligning interior painting Pincourt expectations with a clean, consistent finish.

What surface preparation and skim-coating steps do you use in Pincourt homes to eliminate roller marks, brush strokes, old caulking gaps and ensure paint adhesion before the finish coats?

🖌 Inspection, cleaning, and substrate prep in Pincourt homes

We start with a detailed inspection under raking light to map roller marks, brush strokes, and failed joints specific to Pincourt homes. Surfaces are cleaned with a TSP substitute, rinsed, and deglossed where needed to promote paint adhesion on previously coated or oily areas. We sand with dust-extracting tools (120–150 grit) to flatten nibs and open the surface for primer. Edges are feathered, dust is vacuumed and tack-wiped, and any loose paint is removed to build a stable base for the finish coats.

🖌 Skim-coating steps to remove roller marks and brush strokes

We apply targeted or full skim-coating using setting-type or lightweight joint compound to level roller marks and brush strokes common in repainted Pincourt homes. Wide knives (10–14 in.) are used to pull tight coats, with fiber tape added over hairline cracks or crazing for stability. After drying, we sand with 180–220 grit using HEPA extraction and check under raking light to ensure uniform texture. High-build primer may be used between passes when texture is severe, then a final feather sand creates a consistent profile for paint adhesion.

🖌 Addressing old caulking gaps, priming, and adhesion checks before finish coats

Old caulking is cut out and replaced with a paintable acrylic-silicone caulk, then tooled for proper joint shape and cured per the data sheet. Patch-throughs and mixed substrates are sealed with a bonding or stain-blocking primer; glossy or patchy walls may receive a full prime to even porosity before the finish coats. We verify paint adhesion with a tape-pull or cross-hatch test and adjust primer or prep if needed. Environmental conditions—temperature, humidity, and ventilation—are controlled to support consistent drying in Pincourt homes.

How do your interior painters Pincourt choose and apply durable, low-VOC and moisture-resistant finishes for bathrooms, windows and high-traffic areas to prevent peeling, bubbling and mildew?

🖌 Choosing the right low-VOC, moisture-resistant system

We match coatings to substrate, humidity load, and cleaning frequency. For bathrooms, we specify low-VOC (often under 50 g/L) acrylics labeled bath & spa with EPA-registered mildewcides and high vapor permeability to reduce blistering. For windows and trim, we favor waterborne alkyd or urethane-fortified enamels that offer hardness, block resistance, and edge retention. High-traffic walls get Class 1 scrub-rated finishes (ASTM D2486) with stain resistance to withstand frequent wash-downs. As interior painters Pincourt, we verify primer–topcoat compatibility through product data sheets before selection.

🖌 Surface preparation that prevents failure

We remove soap scum and biofilm with a TSP substitute, then treat visible mildew using a bleach solution (per label) or hydrogen-peroxide cleaner, rinse thoroughly, and dry the substrate to under ~15% moisture. Glossy or peeling areas are deglossed and feather-sanded, dust is HEPA-vacuumed, and surfaces are solvent-wiped to improve adhesion. Gaps and joints are sealed with paintable, mold-resistant caulk; bare wood—especially around windows—is spot-primed with shellac on knots and covered with a bonding/stain-blocking primer for tannins. This sequence stabilizes the surface in wet zones and along traffic paths, reducing the risk of peeling and bubbling.

🖌 Application and curing conditions

We control film build to roughly 2–3 mils dry per coat, using quality microfiber rollers and tapered sash brushes to avoid over-application. Window edges and sash are back-primed, and moving parts receive coatings with high block resistance to minimize sticking. Temperature and RH are kept near 18–24°C and below 60% RH with active ventilation; showers are postponed for 72 hours, with 7–14 days allowed for full cure. Maintenance includes pH-neutral cleaning and periodic inspection of caulk and corners to limit mildew and moisture intrusion.

How do you manage scheduling, on-site protection and cleanup in occupied Pincourt residences so work happens around family life and minimizes disruption to daily routines?

🖌 Scheduling around family life in Pincourt

Before work begins, we map school runs, nap times, remote-work meetings, and quiet hours within permitted Pincourt noise bylaws. We offer morning or afternoon blocks with defined arrival windows, plus a daily start/stop plan for occupied Pincourt residences. Noisy milestones are batched into short windows and timed away from mealtimes and bedtime routines. Same-day text updates confirm progress, next-day steps, and any adjustments needed for family commitments. When a weekday window is tight, we can arrange split shifts or a Saturday slot.

🖌 On-site protection in occupied Pincourt residences

Access paths are shielded from the entry to the work zone using ram board, neoprene mats, and corner guards. We isolate spaces with zipper poly walls, cover return air grills, and use HEPA filtration with negative pressure when dust is generated. Furnishings are wrapped or relocated; kitchens, baths, and nursery areas stay separated from tool staging and material storage. Pets and children are considered in the layout, with magnetic barriers, door sweeps, and labeled hazard zones to reduce cross-traffic.

🖌 Cleanup routines and communication

We structure scheduling, on-site protection and cleanup as a daily cycle: mid-day tidy, end-of-day reset, and a brief review. Floors are HEPA-vacuumed, surfaces damp-wiped, and debris bagged and removed within allowed hours for Pincourt collection or private hauling. Ventilation runs to clear odors; we remove trip hazards, coil cords, and keep clear routes to bedrooms, kitchen, and bathrooms overnight. A quick walk-through or photo update records completed work, open items, and safety considerations before lock-up.

What quality-control inspections, touch-up protocols and trim/detail techniques does Walls Painting perform in Pincourt homes to achieve seamless room-to-room transitions and factory-smooth walls?

🖌 Quality-control inspections for factory-smooth walls

Before painting, we conduct quality-control inspections using raking light at 45° and daylight checks to map every flaw on drywall and plaster. Tape dots identify nail pops, joint ridges, pinholes, and sheen irregularities for methodical repair. We patch with setting compound, sand progressively to P150-P220, spot-prime, and re-inspect until the surface feels factory-smooth to the touch. In West Island/Pincourt homes, we also verify dryness on prior water-stain areas with a moisture meter and document color and sheen to keep finishes consistent.

🖌 Touch-up protocols that create seamless room-to-room transitions

We box paint to eliminate batch variation and keep a wet edge from ceiling to walls to trim. For localized fixes, we feather-sand, spot-prime, and blend with a mini microfiber roller, then extend to the nearest break line to avoid flashing. When transitions cross open plan spaces, we align cut-lines with natural breaks, maintain consistent film build, and stage coats on adjacent rooms the same day for uniform sheen. These touch-up protocols support seamless room-to-room transitions across Pincourt interiors.

🖌 Trim/detail techniques tailored to West Island/Pincourt homes

We set crisp trim lines by masking with delicate-surface tape, cutting by hand with an angled sash brush, and removing tape within the recommended window for a razor edge. Gaps are sealed with acrylic caulk, nail holes are filled, sanded to P220, and primed; MDF gets a bonding primer and tannin-prone woods receive shellac where needed. Doors, cabinets, and wainscoting are finished to a factory-smooth feel using fine-finish spray tips (210/310) or high-density foam rollers with light tip-off. These trim/detail techniques complement the quality-control inspections and touch-up protocols used by Walls Painting to keep transitions tight and finishes even.

Which color consultation services and long-term maintenance recommendations do you offer Pincourt homeowners to select timeless palettes that reflect local natural light and stay modern for years?

🖌 In-home color consultation services tailored to Pincourt light

We provide on-site color consultation services for Pincourt homeowners, starting with a lighting and materials audit. We map room orientation, window size, and seasonal daylight shifts near the St. Lawrence, then evaluate existing finishes that influence undertones. We test large-format swatches with varied light reflectance values at morning, midday, and evening to see how local natural light changes hue perception. We then refine two or three cohesive schemes covering walls, trim, ceilings, and accents to align with flooring, counters, and exterior views.

🖌 TPalette frameworks that stay modern for years

To create timeless palettes, we prioritize mid-to-high LRV neutrals (about 55–75) with moderated chroma, pairing them with one restrained accent per zone. Balanced warm–cool neutrals (greige, taupe, softened white) suit Pincourt’s warm summer sun and cool winter light, supporting furnishings that evolve over time. We coordinate sheen by function—eggshell for walls, satin or semi-gloss for trim and doors—to control glare and improve cleanability. We validate undertones against fixed elements and apply a 60/30/10 proportion so updates remain straightforward and the look stays modern for years.

🖌 Long-term maintenance recommendations and upkeep schedule

Our long-term maintenance recommendations include a care plan and recoat timelines suited to Pincourt’s freeze–thaw cycles. Indoors, use pH-neutral cleaners, keep a labeled touch-up kit, and plan repaint cycles of roughly 5–7 years in high-traffic rooms and 7–10 years elsewhere. Outdoors, wash annually in spring, monitor south- and west-facing elevations for UV fade, and expect 6–10-year recoats for quality acrylic on siding, sooner for doors and trim. Maintain indoor humidity around 40–50% to reduce flashing and caulk issues, and document all color formulas for precise future matching.