Interior painting in Baie-D’Urfé for smooth, uniform walls and brighter rooms that stay easy to clean

Cleaner, brighter rooms—interior painting Baie-D'Urfé by Walls Painting

Why interior painting Baie-D'Urfé often fails

| What homeowners often get | What Walls Painting delivers |

|---|---|

| Marks and grime won't wipe away. | Stains gone; walls clean and even. |

| Fine cracks around doors and windows. | Cracks filled; surfaces smooth and solid. |

| Ceilings show leaks, stains, and shadows. | Fresh ceilings; uniform, brighter rooms. |

| Scuffed walls, chipped trim and railings. | Durable coats; crisp baseboards and trim. |

Get a quote from interior painters Baie-D’Urfé.

About us

We know how it feels when walls won’t wipe clean—grime, hairline cracks, water stains, nail holes, and dulled finishes that make rooms look tired. Life’s busy, but your home shouldn’t show it. We’re here to reset the canvas.

With Walls Painting, you get careful prep and even, durable coats for brighter ceilings and trims, smoother surfaces, and a cohesive flow room to room. We make maintenance easy and results last—professional interior painting Baie-D’Urfé homeowners can trust.

Local team, clean work, clear communication—and it shows. Our neighbors rate us 5/5 on Google. When we finish, stains, scratches, and dents are gone, and your space looks sharper, lighter, and finally consistent from hallways to living areas.

What our loyal customers say about us

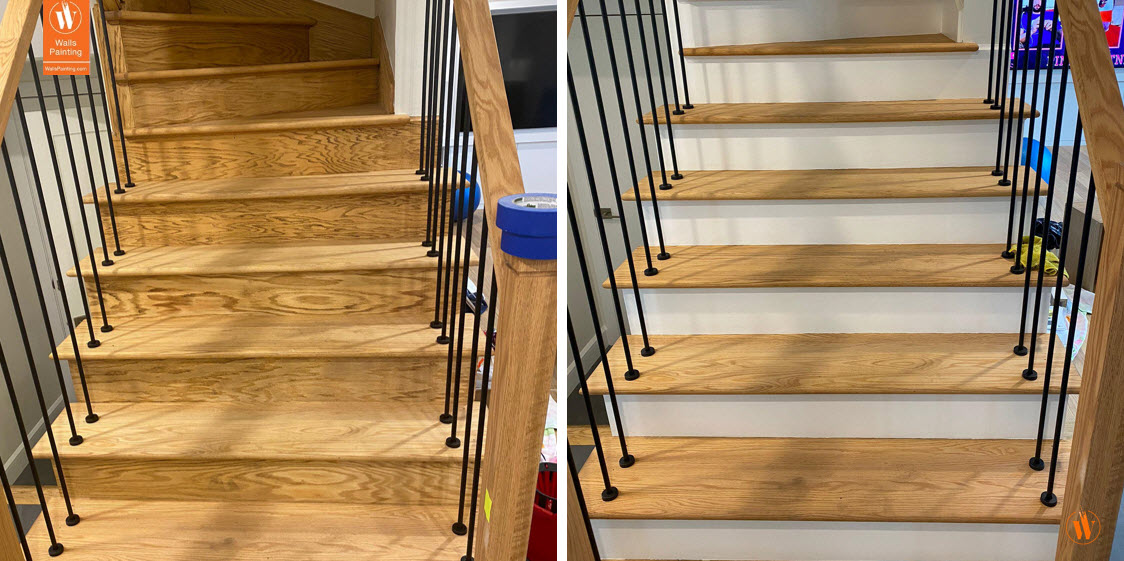

Our Signature in Action

Discover a selection of our most impactful projects, showcasing the quality, creativity, and expertise we bring to every client collaboration

Simple, Structured, Effective—Start to Finish

Plan & Price

We visit, assess issues, recommend colors, and give a clear, fixed quote for interior painting Baie-D'Urfé.

Prep & Protect

Our interior painters Baie-D’Urfé repair cracks, block stains, protect surfaces, and sand dustless for smooth, clean walls.

Paint & Perfect

We apply durable coats, restore trims, clean up fully, and walk through with you to ensure flawless results.

Not every interior painting Baie-D'Urfé project is the same—choose the right service

Repair hairline cracks, patch nail holes, skim dents, and degloss greasy or marked areas before paint. Proper prep delivers smoother walls, blocks stains, and ensures new color looks even and lasts.

Align finishes and tones from room to room for a cohesive flow. We color-match transitions, remove mismatched patches, and apply uniform sheens so spaces feel larger, calmer, and thoughtfully connected.

Brighten ceilings and sharpen baseboards, casings, and doors with crisp lines. Fresh contrast lifts the whole room, hides past touch-ups, and replaces dull, chipped finishes with clean, durable surfaces.

Not sure which option fits your home best? Speak with a Walls Painting representative to clarify scope, finishes, and timelines.

Our Commitment to Care and Follow-Through

From first walkthrough to final clean-up, Walls Painting follows a documented process: detailed surface assessment, written scope, protected furnishings, meticulous prep, and daily site checks to keep your project organized, predictable, and professionally managed.

As your team for interior painting Baie-D’Urfé, you have a dedicated point of contact, proactive updates, and check-ins. We set expectations upfront, answer fast, and remain available on-site and by phone from start to finish.

When conditions change, we adapt. Walls Painting fine-tunes prep, repairs, colors, and scheduling, and we document changes before proceeding. We provide aftercare guidance, touch-up notes, and a post-job walkthrough to ensure your questions are addressed.

Ethics first, transparency always: clear pricing, honest timelines, documented steps, and respectful conduct—Walls Painting is committed to doing the right work, the right way, every day.

Interior painting available across nearby service areas

FAQ

How does Walls Painting guarantee consistent results for interior painting Baie-D'Urfé projects when older homes have uneven patches, faded rooms, or mismatched finishes?

🖌 Diagnostic and preparation for aged interiors

We start with a structured survey of substrates typical in older Baie-D’Urfé homes, noting settlement cracks, prior touch-ups, calcimine, and stains. Adhesion and moisture checks inform whether repairs require setting compounds, partial or full skim coats, feather sanding, and flexible caulking at movement joints. Primers are matched to conditions—bonding primers for slick areas, stain blockers for water or nicotine, and specialty primers over calcimine—to level porosity and prevent flashing. HEPA-assisted dust control keeps surfaces clean for better bonding, and recurring hairline cracks are taped and skimmed to reduce telegraphing. Where lead may be present, we apply lead-safe containment and cleanup practices.🖌 Color matching, sheen alignment, and room-to-room continuity

For interior painting Baie-D’Urfé projects, we build a color and sheen plan that reflects actual site lighting, testing samples under daylight and warm LEDs to reveal metamerism. We box paint across gallons, tint primers toward the finish color, and standardize sheen so ceilings, walls, and trim read uniformly. Deliberate transition points and crisp edge lines prevent accidental sheen breaks between old and newly painted zones. We also align gloss to substrate texture, selecting finishes that minimize the visibility of patches and historical repairs.🖌 Application standards and measurable quality controls

Application follows defined sequencing: consistent cut-ins, wet-edge rolling, and, where appropriate, spray-and-backroll to equalize texture on broad areas. Coverage rates and film build are tracked with wet-film gauges, and scuff sanding between coats improves leveling and adhesion. In-process checks and a final review under multiple light angles help catch lap marks, holidays, or sheen inconsistencies. Product specs, tint formulas, and batch numbers are documented to support future touch-ups and maintain finish continuity over time.Given Baie-D'Urfé’s seasonal humidity and tight contractor schedules, what is a realistic project timeline for whole-room jobs and how do you manage drying times and overall project timeline to minimize disruption?

🖌 Realistic project timeline for whole-room jobs in Baie-D’Urfé

For a repaint with light patching, a realistic project timeline is typically 2–4 days in drier months and 3–6 days when Baie-D’Urfé humidity peaks. If the scope includes skim-coating or plaster repairs, plan on 5–10 days in low humidity and 7–14 days during damp periods. Flooring, cabinetry spraying, or tile work can extend whole-room jobs; we sequence these so surfaces cure before adjacent trades return. Furniture reset usually happens 24–48 hours after final coat, while full cure may take longer depending on product specifications.

🖌 Managing drying times under seasonal humidity

Seasonal humidity in Baie-D’Urfé slows drying times for compounds, primers, paints, and adhesives, so we condition the space to 40–55% RH using dehumidifiers and controlled airflow. We verify readiness between coats with moisture readings and product-specific recoat windows rather than fixed clocks. Waterborne coatings and modern compounds are prioritized when appropriate to shorten safe recoat intervals. We also stagger tasks—patching and priming early, finishing coats later—so progress continues while layers dry properly.

🖌 Scheduling strategies to minimize disruption and protect the overall project timeline

Tight contractor schedules in Baie-D’Urfé require locking scope and dates 2–6 weeks ahead and pre-ordering materials 1–2 weeks in advance. We build a 10–20% buffer into the overall project timeline to absorb humidity-related drying variances without compressing workmanship. Where possible, we phase rooms or zones to keep parts of the home functional and consolidate noisy or odor-producing steps. Daily check-ins and milestone sign-offs keep sequencing clear, and protection/cleanup routines at day’s end reduce disruption to normal routines.

What surface preparation do you perform for embedded grime, hairline cracks, and water stains — including the use of stain-blocking primer and patching techniques common in local Baie-D'Urfé homes?

🖌 Degreasing and stain isolation

We start by assessing embedded grime, hairline cracks, and water stains under bright, raking light. Embedded grime is removed with a biodegradable TSP substitute, followed by two clean-water rinses and full dry time—important in Baie-D’Urfé homes where Lake Saint-Louis humidity can slow drying. For water stains, smoke, or tannin bleed, we spot-seal with a shellac or oil-based stain-blocking primer to prevent discoloration from telegraphing through. On glossy or previously oil-painted areas, we scuff-sand and apply an adhesion-promoting primer before any patching or finish coats.

🖌 Patching techniques for hairline cracks and defects

To stabilize hairline cracks, we lightly V-groove the fissure, vacuum out dust, and, on chalky plaster common in Baie-D’Urfé homes, apply a bonding agent. We fill with a setting-type joint compound, embedding fiberglass mesh where movement is suspected, a patching technique that adds dimensional stability. Repairs are built in thin coats, feathered 8–12 inches, then sanded to 180–220 grit and checked with raking light. This sequence helps the repair blend invisibly while addressing embedded grime, hairline cracks, and water stains that can compromise adhesion.

🖌 Moisture control and whole-surface priming

Before coating, we verify that areas with water stains have a moisture content at or below 16% and that sources like roof leaks or condensation are addressed. Gaps at trim and window casings are caulked with paintable acrylic-silicone to reduce drafts and seasonal movement in Baie-D’Urfé homes. We then prime patched zones—or, when porosity varies, the entire wall—to create a uniform surface for finish coats. This measured approach targets embedded grime, hairline cracks, and water stains while supporting consistent color and adhesion.

Which materials and health-focused options do you offer (for example low-VOC paints and mildew-resistant coatings) that suit family homes in our area and improve indoor air quality after painting?

🖌 Low-VOC and zero-VOC paint systems

We specify low-VOC and zero-VOC paints, including bases and VOC-free colorants, to help improve indoor air quality after painting in family homes. We prioritize products verified to GREENGUARD Gold or Green Seal GS-11, and request SDS showing VOC content (often ≤5 g/L after tinting). Where durability is needed, we use low-odor, waterborne alkyds for trim and doors to reduce solvents compared with traditional alkyds. We also screen for formulations that are formaldehyde-free, APEO-free, and phthalate-free to align with health-focused options in our area.

🖌 Mildew-resistant coatings for moisture-prone rooms

In bathrooms, kitchens, and basements, we apply mildew-resistant coatings that use EPA-registered mildewcides and demonstrate strong performance on ASTM D3273. Satin or semi-gloss finishes are selected for washability while keeping emissions low, which supports indoor air quality after painting. On masonry or older walls in our area, we prefer breathable acrylic systems that manage vapor while resisting mildew. We pair these with stain- and odor-blocking waterborne primers to limit recurring discoloration and musty smells in family homes.

🖌 Application and aftercare to improve indoor air quality

We reduce particulates with HEPA sanding and dust containment, then use low-odor, waterborne primers to complement low-VOC paints. After application, we recommend cross-ventilating spaces for 48–72 hours, upgrading HVAC filters to MERV-13 where feasible, and using HEPA plus activated-carbon purifiers to capture both particles and VOCs. We seal gaps with low-VOC caulks/adhesives and avoid two-component isocyanate systems indoors. For family homes in our area, we schedule work so children and pets are away during early curing to further improve indoor air quality after painting.